Wafer Chucks

Arcnano manufactures both OEM replacement and custom wafer chucks in porous ceramic, stainless steel, Ni plated copper and other materials.

We achieve < 2um flatness and parallelism over 150mm and < 8um over 300mm.

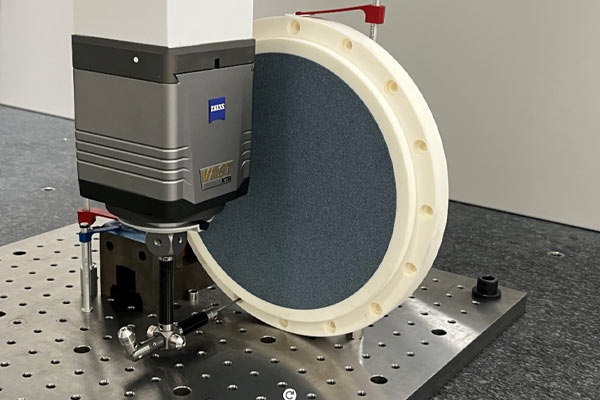

6” Arcnano model of vacuum chuck (generic) with vacuum attach