5-Axis CNC Machining

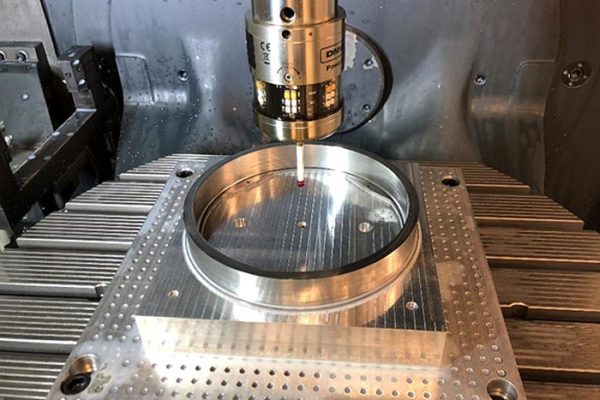

Arcnano performs simultaneous 5-axis CNC Machining, providing complex machined parts to tight tolerances with fewer set-ups.

Currently, Arcnano’s workpiece envelope is approximately 400 to 450 mm in X&Y with 300 to 400 mm in Z. DMG 5-axis machines with Siemens controllers are widely deployed at Arcnano.

Arcnano utilizes Erowa Systems Solutions, https://www.erowa.com/en, workholding and pallet systems which enable instantaneous transfer of the pallet to-and-from the CMM inspection center with less than 1 micron of displacement accuracy.

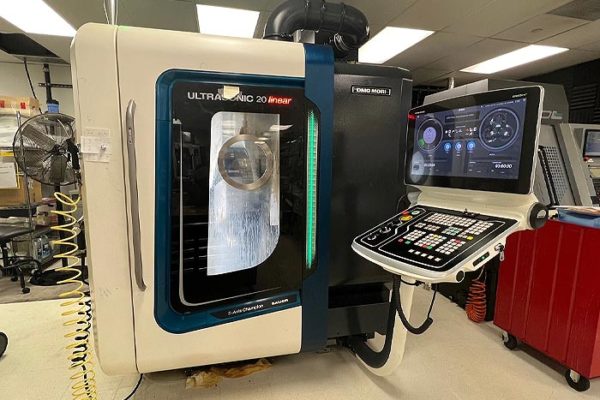

5-Axis Ultrasonic Machining

Arcnano uses its 5-axis Linear Ultrasonic High-Speed Machining for tight tolerance machining of traditional and exotic materials. The DMG Linear 20 Ultrasonic Machining Center is at the forefront of advanced machining technology. The optionable ultrasonic machining mode allows for a wide range material and design applications.

Arcnano machines ceramics, including Alumina, Zirconia, and Silicon Carbide and other challenging materials such as Tantalum, Titanium and metal matrix composites, such as Materion’s AlSiC material, brand name SupremeX.

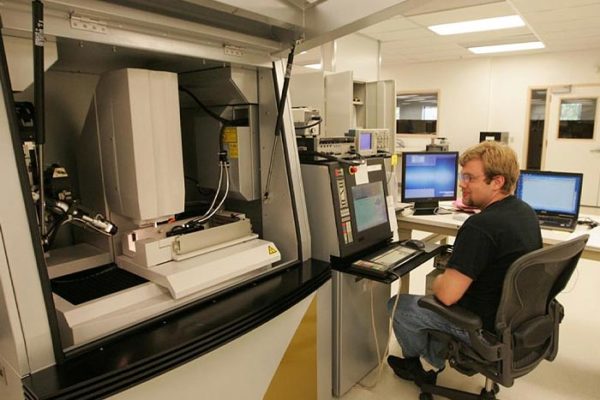

3-Axis CNC Linear High-Speed Machining

For our 3-axis high speed machining needs. Arcnano uses the Sodick Linear 430 which has a positional accuracy of 0.25 micron over an envelope of 430mm X and 300mm in Y and Z, and with a 40k rpm spindle. This machine combines extreme precision with high-speed milling of very hard materials.

The combination of high precision and high speed make this machine ideal for 3-axis micro machining of traditional materials such as hardened tool steel, stainless steel and aluminum and exotic materials including ceramics.

Wire EDM

With both the AP 200 and the ALN 600 Sodick Wire EDM Machines, Arcnano can meet all your wire EDM needs. Both machines have rotary and turn & burn attachments.

The AP 200 is an oil dielectric machine and can utilize wire diameters from 100 mm (4 mil) down to 30 mm (1.2 mil).

The ALN 600 is a water EDM where 10 mil wire (250 mm) is typical.

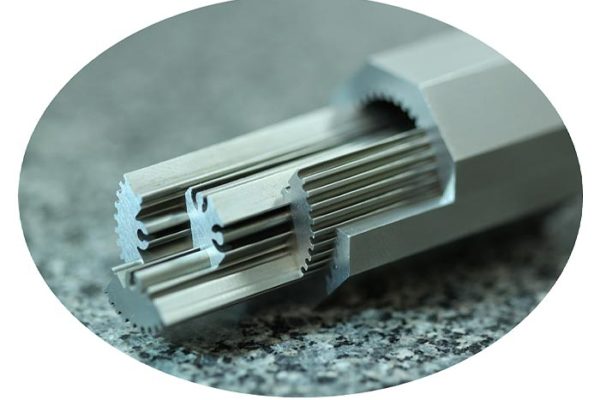

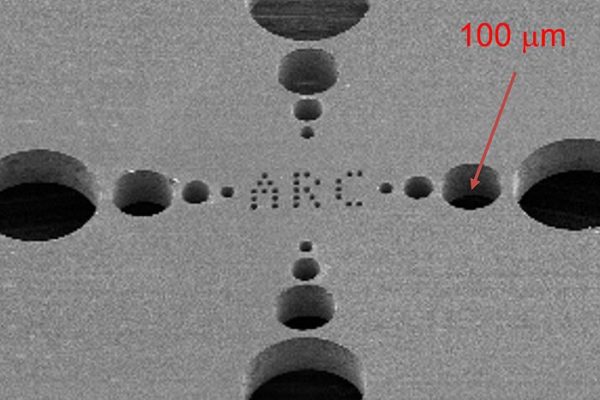

Micro Sinker EDM

With sub micron position accuracy and the ability to form an electrode with insitu electrode measurement, the Sodick AE-05 Micro Sinker EDM is the most accurate micro EDM in the world.

Arcnano uses this extraordinary sinker EDM to manufacture FIB Aperture Strips (see micro-site- www.arcapertures.com) and various other apertures for electron microscopy, X-ray and Photonic applications.

Grinding, Lapping, & Polishing

Arcnano provides backside grinding, lapping and polishing services to meet our customers needs. Our CNC Surface Grinders, fitted with air bearing spindles, are used for grinding metals and ceramics, such as Alumina and Silicon Carbide. This grinding expertise is complimented by lapping and polishing machines ranging from 12 to 48 inches in diameter.

Additionally, Arcnano provides backside grinding services, thinning, lapping and polishing for compound semiconductor substrates such as SiC, GaN, Indium Phosphide (InP), Gallium Antimonide (GaSb) and others.

- Air Bearing Spindles

- CNC Grinders

- Lapping

- Polishing

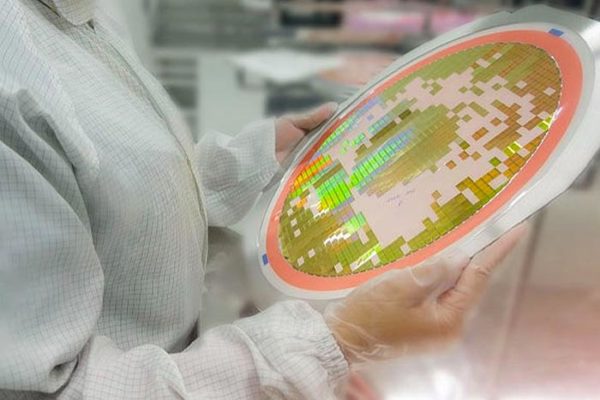

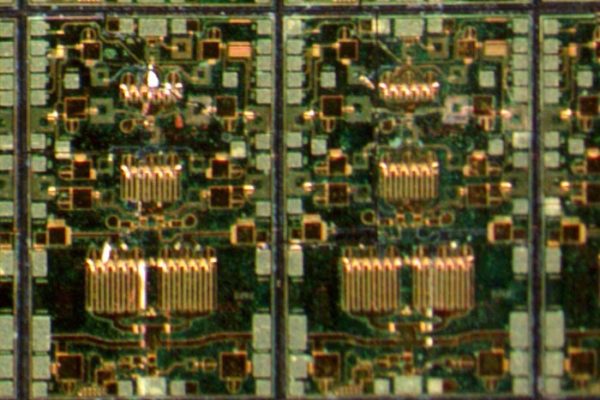

Wafer Dicing

Semiconductor Back End Fabrication is a specialty at Arcnano.

Arcnano’s Disco Hi-Tech wafer dicing saws have higher power spindles which can easily dice ceramics, such as Alumina, as well as various semiconductor wafers. Arcnano thins and dices up to 200 mm wafers.

Additionally, Arcnano has expertise with special applications with SOI, ceramic, glass and other materials.

- Silicon

- Compound Semi

- Ceramics

- Glass